DreamzIoT excels in PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) programming, delivering tailored solutions for industrial automation. Our expert team employs cutting-edge programming languages and tools to develop PLC logic and HMI interfaces that seamlessly integrate with diverse manufacturing processes. We prioritize user-friendly interfaces for intuitive control and monitoring. DreamzIoT’s PLC/HMI programming ensures precise automation, rapid response to system changes, and efficient data visualization. Our solutions empower industries to achieve enhanced productivity, reduced downtime, and improved overall operational efficiency. Trust DreamzIoT for state-of-the-art PLC/HMI programming solutions that align with your specific industrial automation needs.

PLC (Programmable Logic Controller) Programming:

- Purpose: PLCs are digital computers used for controlling manufacturing processes, machinery, and other automation systems. They play a key role in automating repetitive tasks, monitoring inputs, and controlling outputs.

- Programming: PLC programming involves creating a set of instructions that dictate how the PLC should operate. These instructions, often written in ladder logic or other programming languages, define the logical operations and control sequences needed to achieve specific tasks.

- Functions: PLCs are used for tasks such as controlling motors, valves, sensors, and other devices in a manufacturing environment. They ensure precise control, rapid response to changes, and the ability to adapt to different scenarios.

HMI (Human-Machine Interface) Programming:

- Purpose: HMIs are interfaces that allow human operators to interact with and monitor the PLC-controlled systems. They provide a visual representation of the industrial process and enable users to input commands and receive feedback.

- Programming: HMI programming involves designing and configuring the graphical user interface that operators use to control and monitor the industrial processes. This may include creating screens, buttons, alarms, and data visualization elements.

- Functions: HMIs facilitate real-time monitoring, control, and troubleshooting of industrial systems. They aim to provide an intuitive and user-friendly interface for operators to interact with the underlying PLC logic.

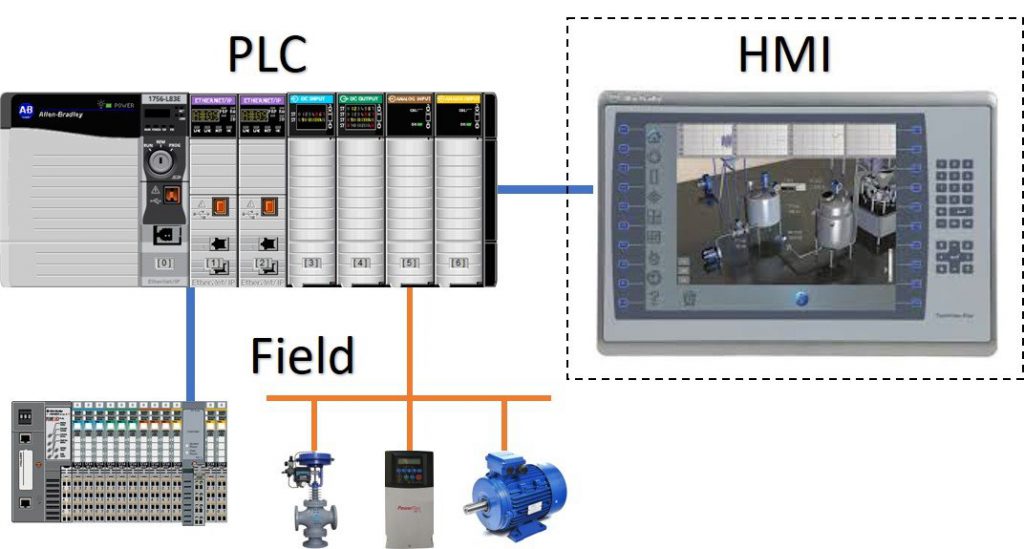

Integration:

- PLC and HMI systems are often integrated to work together seamlessly. The PLC handles the control and logic aspects, while the HMI provides the user interface for monitoring and interacting with the process.

- Information from the PLC is displayed on the HMI, and operators can use the HMI to send commands or adjust parameters, creating a symbiotic relationship between the two.

In summary, PLC and HMI programming are integral parts of industrial automation, working together to ensure efficient control, monitoring, and operation of manufacturing processes.